PVC / WPC Ua Npuas Ncauj Board Ntau Lawm Kab

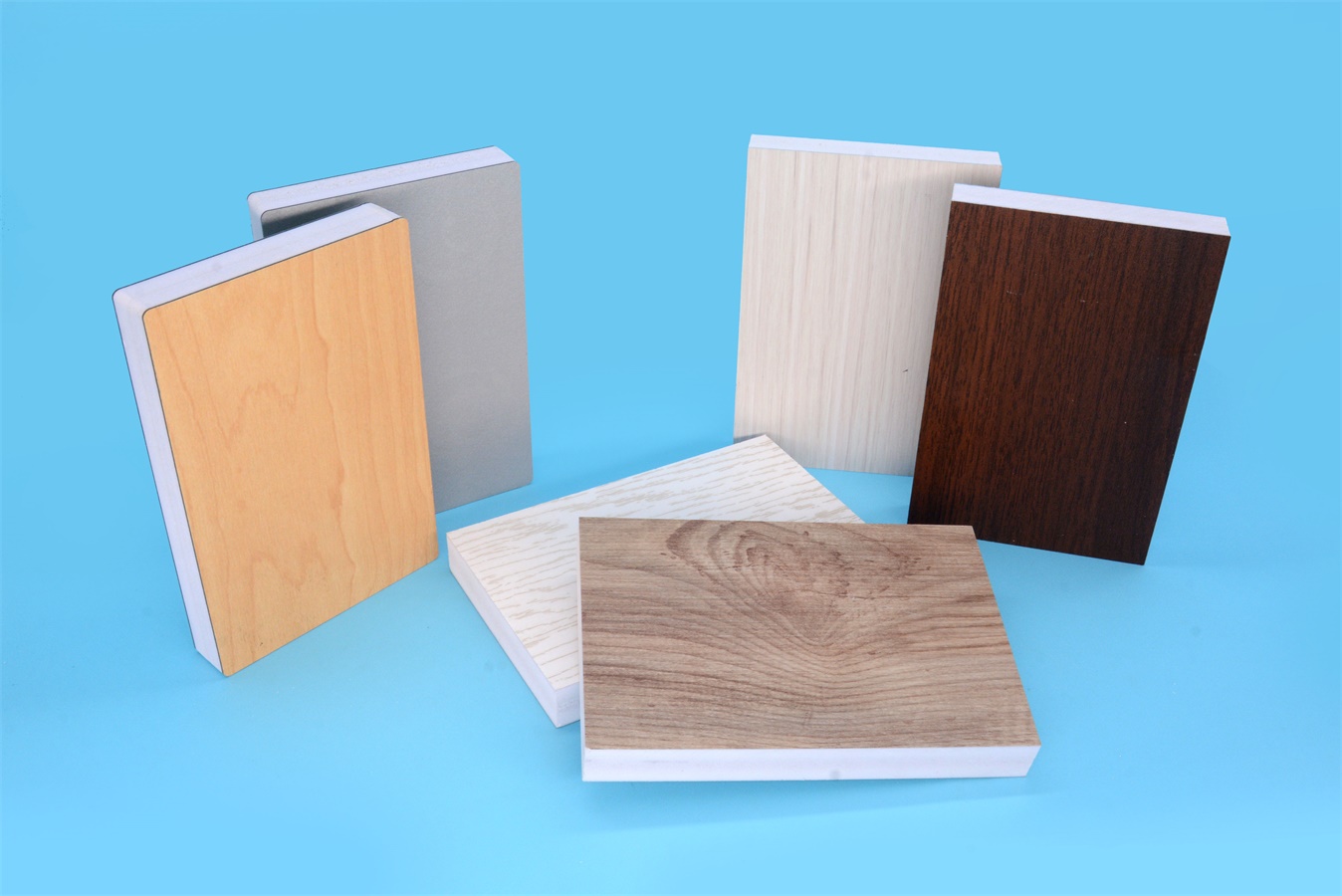

Qhov no PVC / WPC Ua Npuas Ncauj Board ua kab yog siv los ua cov khoom siv kho kom zoo nkauj rau chav ua noj, rooj tog zaum, chav dej board, lub tsev qauv, kev tsim vaj tsev, WPC flooring substrate, billboard, thiab lwm yam.

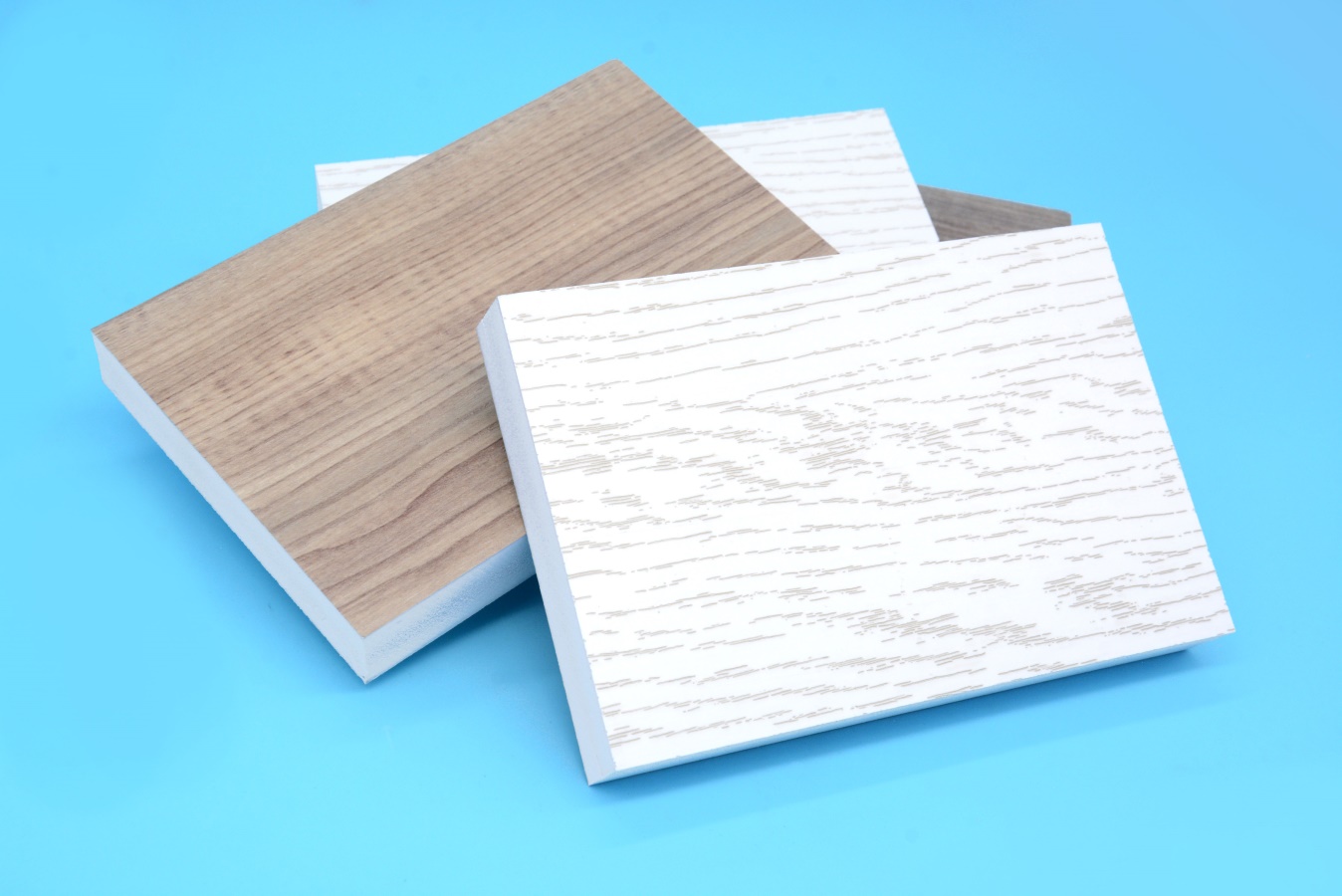

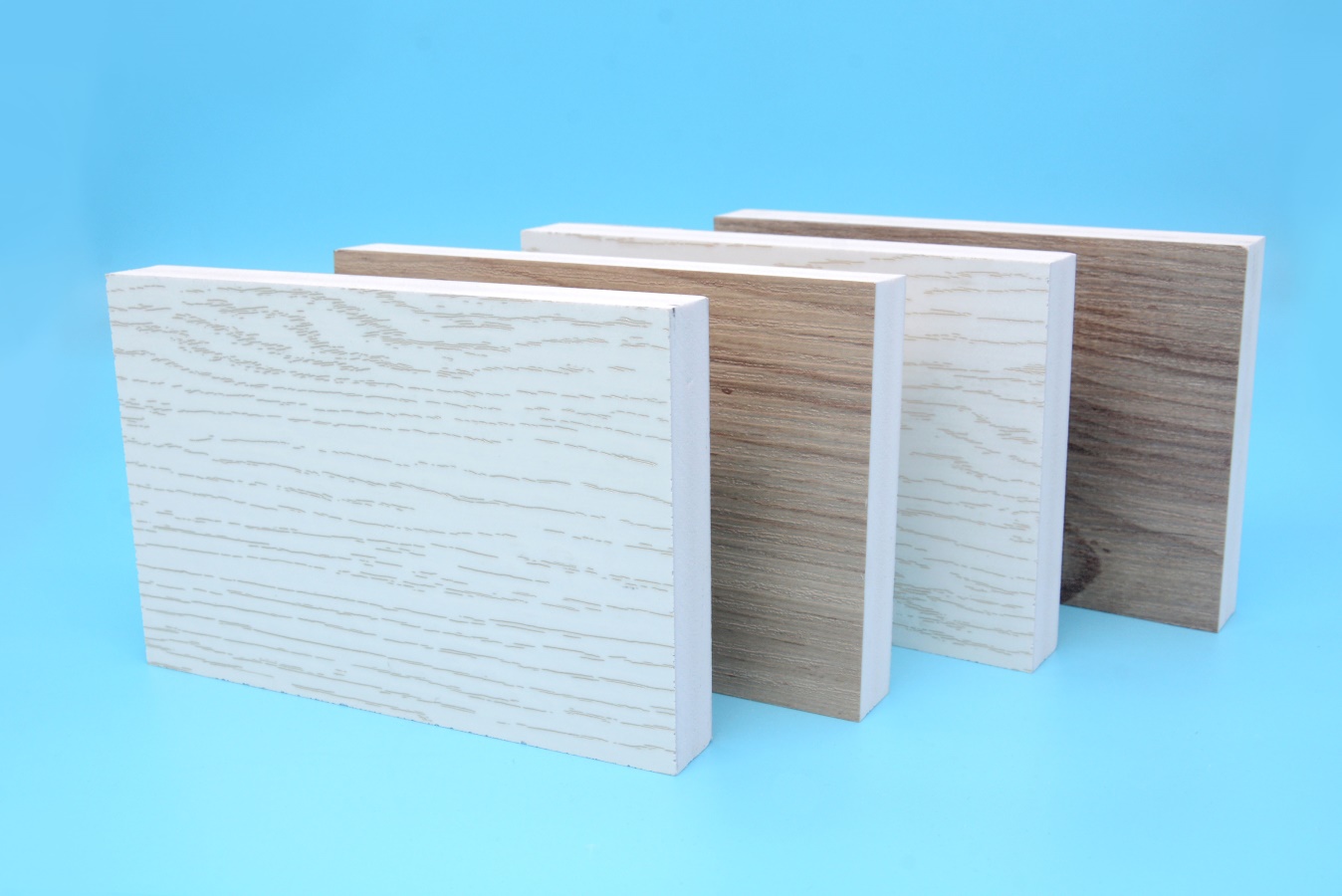

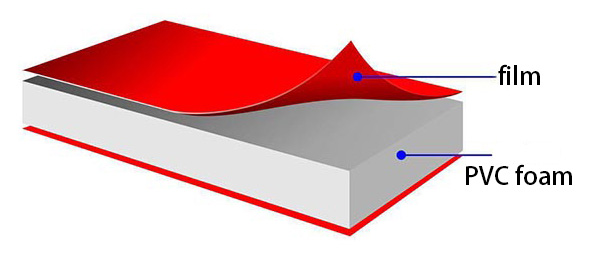

Lub rooj tsavxwm ua npuas ncauj yog ib hom PVC ua npuas ncauj los yog WPC ua npuas ncauj board.Muaj laminated zaj duab xis los yog daim ntawv ntawm thawj txheej raws li decorating nto.

nrog lub siab ceev PVC ua npuas ncauj los yog WPC ua npuas ncauj board nyob rau hauv nruab nrab, uas yog xaiv raws li lub substrate kom ntxiv dag zog rau nws tuav lub hwj chim.

Ua tsaug rau nws cov khoom siv zoo heev, ntxiv rau ntau yam khoom siv lamination thiab hloov tau yooj yim & ntau hom kev xaiv, lub rooj tsavxwm feem ntau yog siv hauv kev lag luam rooj tog thiab cov khoom siv zoo rau cov khoom siv ntoo.

Nws tuaj yeem yooj yim sawed, stamped, punched, sanded, drilled, screwed, nailed, riveted, los yog bonded.

Cov txiaj ntsig ntxiv ntawm cov khoom yog ntub-pov thawj, dej-resistant,

Tshuab specification & technical data:

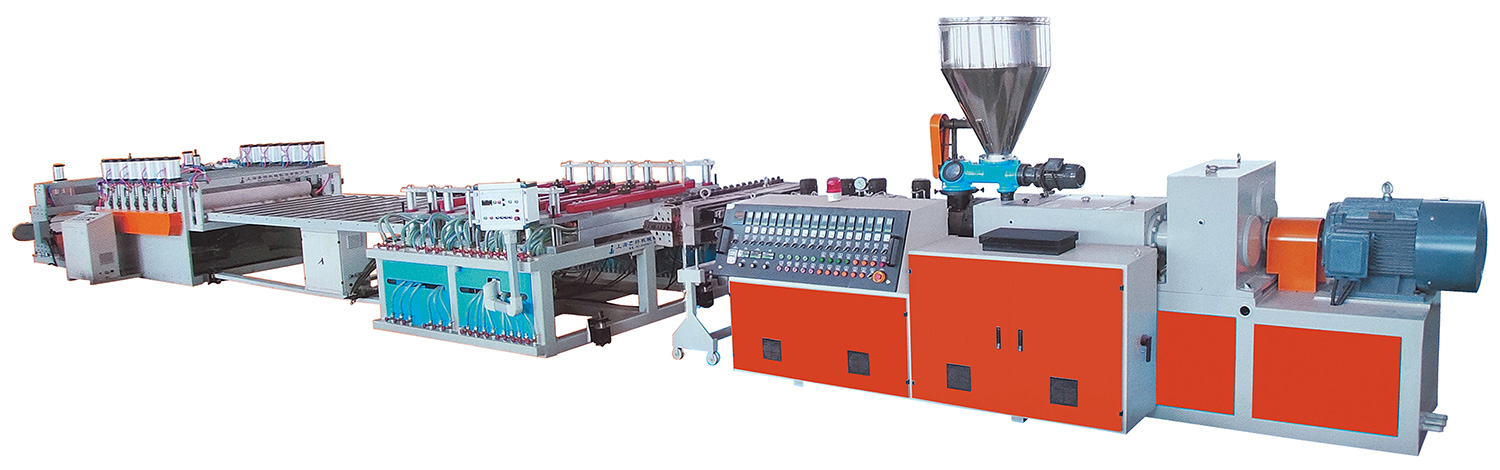

PVC WPC ua npuas ncauj board / pem teb substrate ntau lawm kab yog tsim los ntawm extruder, pwm, ua npuas ncauj board chaw tshuab, ntuj txias system, tsheb laij teb, tshiab tiam ntawm precision ua tsis siv neeg tsau-ntev txiav tshuab (frequency conversion ceev tswj), tsis siv neeg cov khoom tiav lawm. platform, thiab tsheb thauj mus los trolley

Qhov khoom loj:

Thickness: 2mm-12mm

Loj: 970mm x 2000mm los yog 1220x2440mm

* Lub zog ntxaib ntsia hlau yas extruder tshuab tau ua kom zoo, lub siab plasticzation muaj peev xwm ntawm cov khoom sib xyaw, lav qhov sib xws ntawm cov yas yaj.

* nrog lub peev xwm loj ntawm cov zis, lub sijhawm no, cov khoom siv kuj ruaj khov.

* Tshwj xeeb tshaj yog nyob rau hauv cov nqe lus ntawm kev ruaj ntseg ntawm foaming coefficient, ib tug tshwj xeeb tsis siv neeg tswj txoj kev yog saws los stabilize lub luj ntawm txhua lub rooj tsavxwm.

* Txais cov plua plav tshwj xeeb thiab sawdust tsis siv neeg sau cov cuab yeej kom txo tau cov pa phem ntawm tag nrho cov kab ntawm cov plua plav mus rau lub rooj cob qhia, ua rau kev lag luam ua kom lub rhiav ib puag ncig huv.

* Precision kho cov tuab ntawm daim ntawv los ntawm cov khaub ncaws zoo siab hom pwm lub taub hau.

* Lub ± 1 ℃ precision kub tswj rau cov txheej txheem plasticization, tuab thiab du nto.

* Ob txoj kev tswj xyuas cov thickness ntawm daim ntawv kom raug los ntawm kev kho cov ntsia hlau los yog roj siab.

* Ob chav voj txias thiab pwm kub tswj tau txais yuav.

* Precision txiav tshuab muab kev ruaj khov thiab raug txiav ntev.

Main Technical Parameters

| Qauv No. | Lub cev muaj zog (KW) | Khoom siv tsim nyog | Cov khoom dav (mm) | Ntau lawm turnover (KGS / teev) |

| WPCFB-C80 | 75 | PVC + CaCO3 / PVC + Ntoo Powder + CaCO3 | 1220 | 400 |

| WPCFB-C80+C65 | 75+37 ib | PVC + CaCO3 / PVC + Ntoo Powder + CaCO3 | 1220 | 500 |

PVC Imitation Marble Sheet Khoom Txheej

| Thawj Txheej | Laminated zaj duab xis |

| Ob Txheej | High density PVC ua npuas ncauj |

| Thib peb | Kho kom zoo nkauj zaj duab xis |

Tshuab Kab

PVC WPC Ua Npuas Ncauj board ntau lawm kab tseem hu ua WPC Flooring ua kab / Yas rooj tog board ntau lawm kab / tsev qauv tsim kab, kev tsim vaj tsev ua kab.

Lub ntsiab chav tsev, yas extruder, yog tsim los ntawm Concial Twin Screw yas extruder nrog muaj zog hmoov tawm.

Lub Twin Screw Yas Extruder tshuab kuj tseem yog chav tsev loj rau cov kab ntau lawm ntawm PVC PIPE, PVC profile thiab lwm yam.

Peb lub tshuab kab muaj tus nqi siab rov qab los ntawm kev nqis peev thiab tuaj yeem them rau lawv tus kheej sai.

Raws li ib tug 20 xyoo experence Hoobkas, peb muaj peev xwm muab cov neeg muas zaub nrog kev pab txhawb nqa thiab txhawb los ntawm raw cov ntaub ntawv formula, ntau lawm txheej txheem rau molding khoom.

Daim ntawv thov